I have been using the cassette feeder for a while, and it helps me managing components well. But after using it for some time, I found there are something I need to improve. When using the cassette feeder, I need to pull out used strip when components are placed, then cut the tape, and the peel off the plastic cover. In this process, it is easier to go wrong, and also it is a lot of manual work. To make it easier, I start designing the new one, my goal is to

- Remove the need to peel off plastic cover

- Reduce the manual cutting and pull out effort

- Reduce the chance component are bouncing off

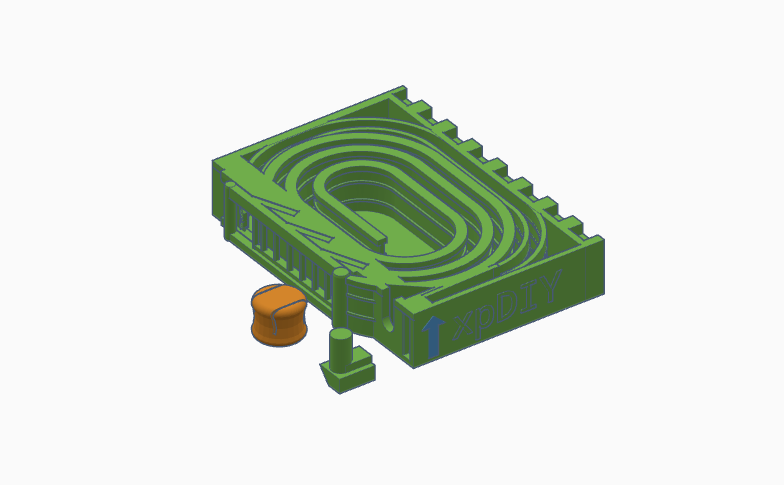

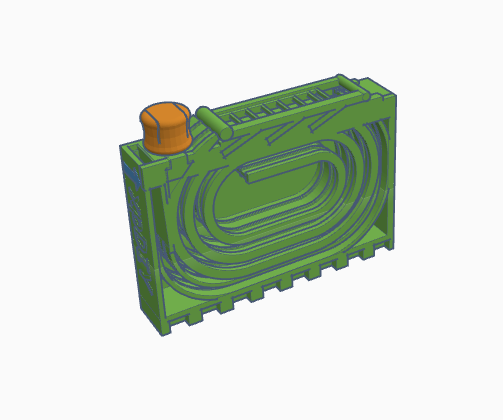

After some brain storming and trial and error, I came up with this, the first thing obvious is – it come with trimmer, and the trimmer is used to rotate and pull the plastic cover. When one is using the feeder, he can rotate the trimmer, it pull the plastic cover and hence pull the strip moving forward.

And also on the right side of the feeder, there is a return path, so empty part of the strip will go in and return out to the left, then one can cut it there.

Second feature is to hold the strip, there is a clipper like structure to apply force to the strip, so that it will stay flat to the surface, this is because when the surface is not flat, component are likely to bounce off, makes the placement job fail. With the clipper structure, it can be moving up and down, to adapt for different thickness of the strip, for ex. 0201 is thinner than 0402 and 0603, with this design, the feeder can accomodate different size of components.

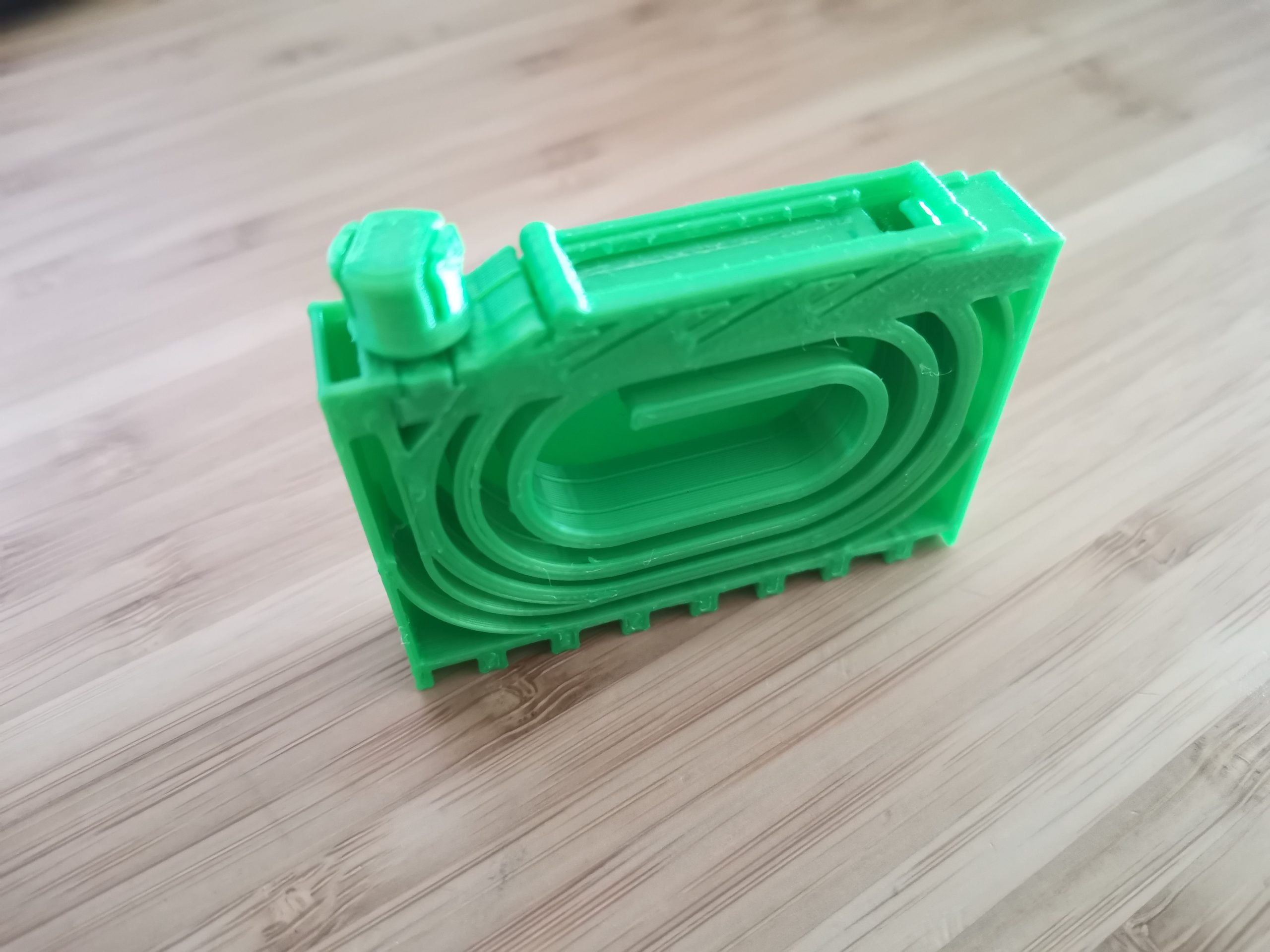

After printing out, it looks like this, I am using 0.3mm layer height and 0.4mm layer width, and because my 3D printer has a bit of elephant foot problem, I use raft to overcome the issue as the precision here is important, it needs to fit the base plate well.

I have uploaded the design to https://www.xpdiy.io/product/cassette-feeder-trimmer-version/ , you can download and try it out, leave comment below if you have any idea and questions. Cheers!